1. Homemade Powder Coating Spray Booth Components and Structure

A Homemade Powder Coating Spray Booth is a DIY enclosure designed to contain overspray and improve coating efficiency. Basic components include a frame (wood, PVC, or metal), ventilation fans, air filters, lighting, and a grounded metal mesh for electrostatic grounding. Enclosures often use inexpensive materials like plastic sheeting or plywood. Advanced setups may integrate cyclone filters or adjustable airflow systems for better powder recovery.

2. Applications of Homemade Powder Coating Spray Booths

These booths are ideal for small-scale projects such as coating automotive parts (wheels, brackets), bicycle frames, furniture, or tools. Hobbyists and small workshops use them for customizing metal crafts or restoring vintage items. They suit low-volume tasks where commercial booths are cost-prohibitive, offering flexibility for garage-based or home-based powder coating operations.

3. Cost of Building a Homemade Powder Coating Spray Booth

A basic DIY booth costs 200–800, depending on materials. Key expenses include:

Ventilation: 50–200 for inline fans and ducting.

Filters: 30–100 for reusable polyester or disposable paper filters.

Lighting: 20–50 for LED strips.

Frame: 50–150 for PVC pipes or wood panels.

Commercial-grade components (e.g., explosion-proof fans) may raise costs to $1,500+.

4. How to Use a Homemade Powder Coating Spray Booth Safely

Setup: Place the booth in a well-ventilated area away from flammable materials.

Grounding: Connect the metal mesh to an earth ground to prevent static buildup.

Spraying: Wear a respirator (NIOSH-approved) and maintain 8–12 inches between the gun and workpiece.

Cleanup: Vacuum overspray frequently and dispose of waste powder properly.

5. Tips for Choosing Materials for a DIY Spray Booth

Size: Match booth dimensions to your largest project (e.g., 4x4x6 feet for car parts).

Ventilation: Select fans with 200–500 CFM airflow for effective dust extraction.

Filters: Use pleated filters (MERV 8+) to capture fine powder particles.

Lighting: Install moisture-resistant LEDs for clear visibility.

6. Safety Precautions for Homemade Powder Coating Spray Booths

Fire Risk: Avoid using near open flames; keep a Class D fire extinguisher nearby.

Dust Explosion: Ground all components and use anti-static materials.

Ventilation: Ensure airflow prevents powder accumulation in the workspace.

PPE: Wear gloves, goggles, and a respirator to avoid inhalation risks.

7. Cost-Benefit Analysis of Homemade vs. Commercial Booths

Homemade booths reduce upfront costs by 80% compared to commercial units ($5,000+). However, they may lack advanced features like automated recovery systems or OSHA-compliant airflow. For low-frequency use, DIY booths offer sufficient functionality, but high-volume operations require commercial-grade safety and efficiency.

8. FAQs on Homemade Powder Coating Spray Booths

Q: What materials are best for a DIY spray booth frame?

A: PVC or aluminum frames are lightweight and corrosion-resistant, ideal for homemade powder coating spray booths.

Q: How to improve airflow in a Homemade Powder Coating Spray Booth?

A: Add multiple inline fans and seal gaps with silicone to maximize ventilation efficiency.

Q: Can I reuse powder collected in a DIY booth?

A: Yes, if filters are clean and powder is uncontaminated—sieve it before reuse.

Q: Are homemade booths safe for epoxy powder coatings?

A: Yes, but ensure proper grounding and ventilation to mitigate chemical exposure.

Q: How to maintain a DIY powder coating spray booth?

A: Clean filters weekly, inspect wiring monthly, and replace worn components promptly.

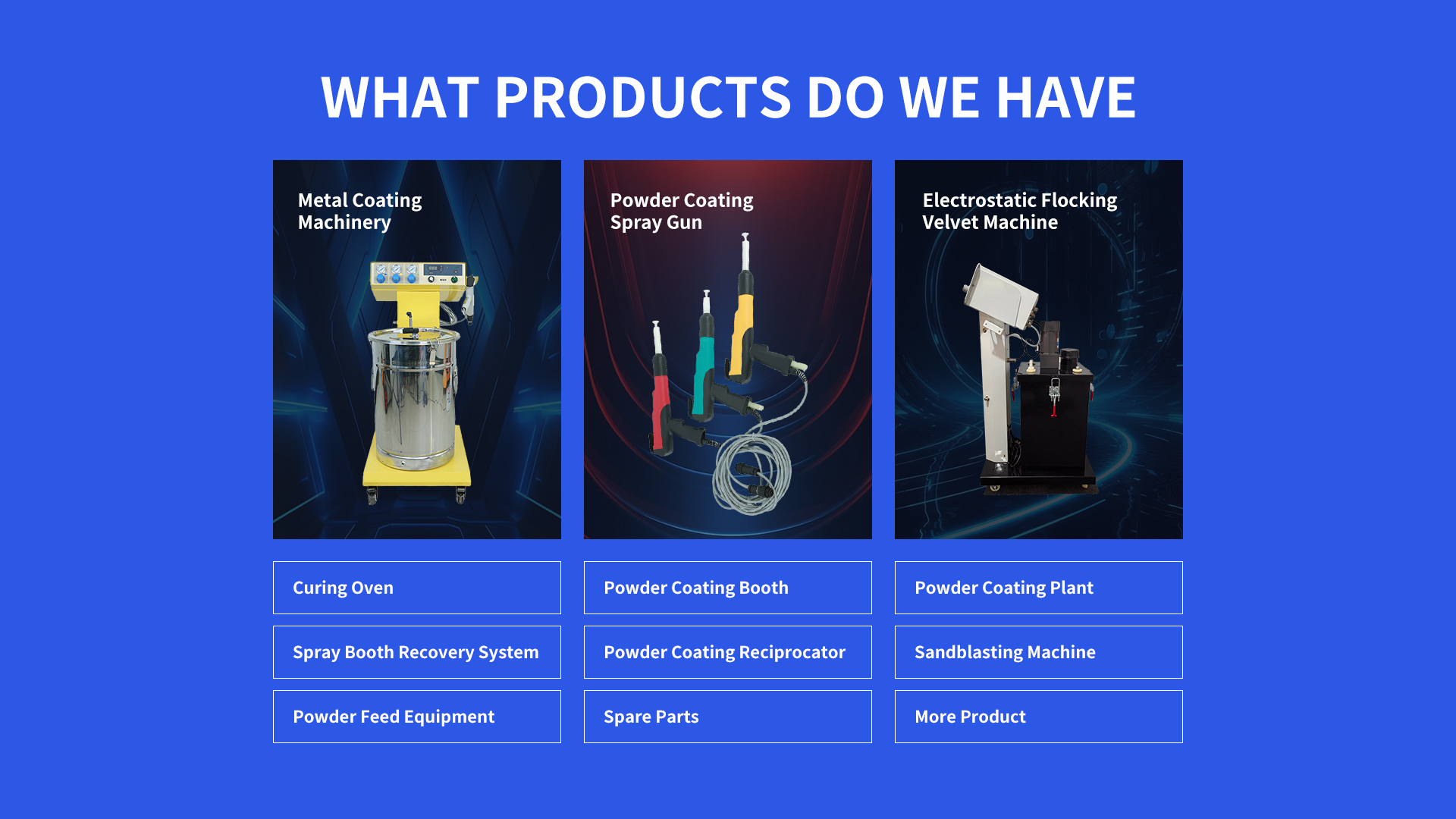

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com